For precisely coated interior geometries Whether adhesive, lubricant, grease, silicone, polyester, or epoxy resin – applying media accurately and precisely inside an interior geometry is a technically demanding task. To enable industrial manufacturers to achieve precisely this with maximum efficiency and precision in cavities, internal threads, or shaft-hub connections, for example, preeflow has added the eco-SPIN to its portfolio. In … Read More

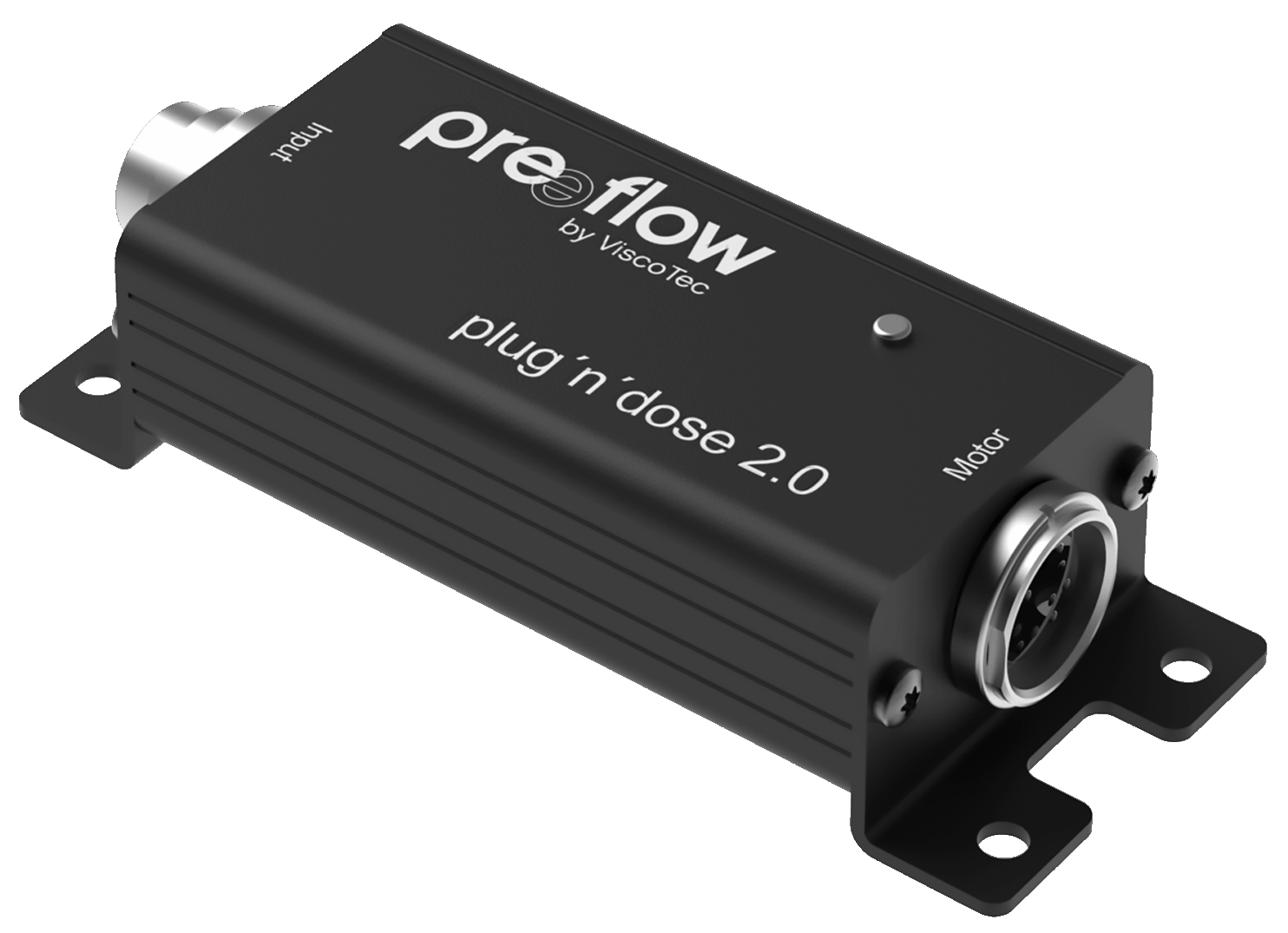

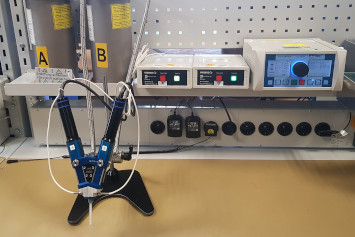

Microcontroller plug’n’dose 2.0

Compact, precise, and flexible for modern dosing processes With the plug’n’dose 2.0, preeflow introduces an advanced miniature dispensing controller that impresses with its reduced size and optimized features. The microcontroller is specifically designed for applications with limited installation space and is 80% smaller than the previous model. At a weight of just 110 g, it is also significantly lighter. A … Read More

productronica 2025 – preeflow microdispensing technology perfectly represented

Vieweg and ViscoTec present the portfolio of eco-PENs and eco-DUOs From November 18 to 21, 2025, productronica will open its doors in Munich. Visit ViscoTec in Hall A4, Booth 435, and Vieweg in Hall A3, Booth 263, to discover the latest solutions for microdispensing fluids and pastes with preeflow dispensers. Both exhibitors will demonstrate how precise, reliable dispensing of the … Read More

Production Using Robots with preeflow Dispensing Technology

Grease application with eco-PEN dispenser Spray application using the eco-SPRAY Dispenser Automated grease application – precise and reliable TQ Systems, in Durach, manufactures collaborative robots that assemble themselves – among other things, with the help of preeflow dispensing technology. The precise eco-PEN and eco-SPRAY dispenser systems take care of the lubrication of gears, for example. The basic idea of letting … Read More

Loudspeaker Bonding in Perfection!

Precise adhesive dispensing to components Thanks to its experience and reliability preeflow is the perfect partner in numerous dispensing applications – also when it comes to bonding loudspeaker components. In the loudspeaker bonding a great value on exact processing is placed to achieve an outstanding sound experience and create long-lasting products. The loudspeaker manufacturer’s latest technical innovations place high demands … Read More

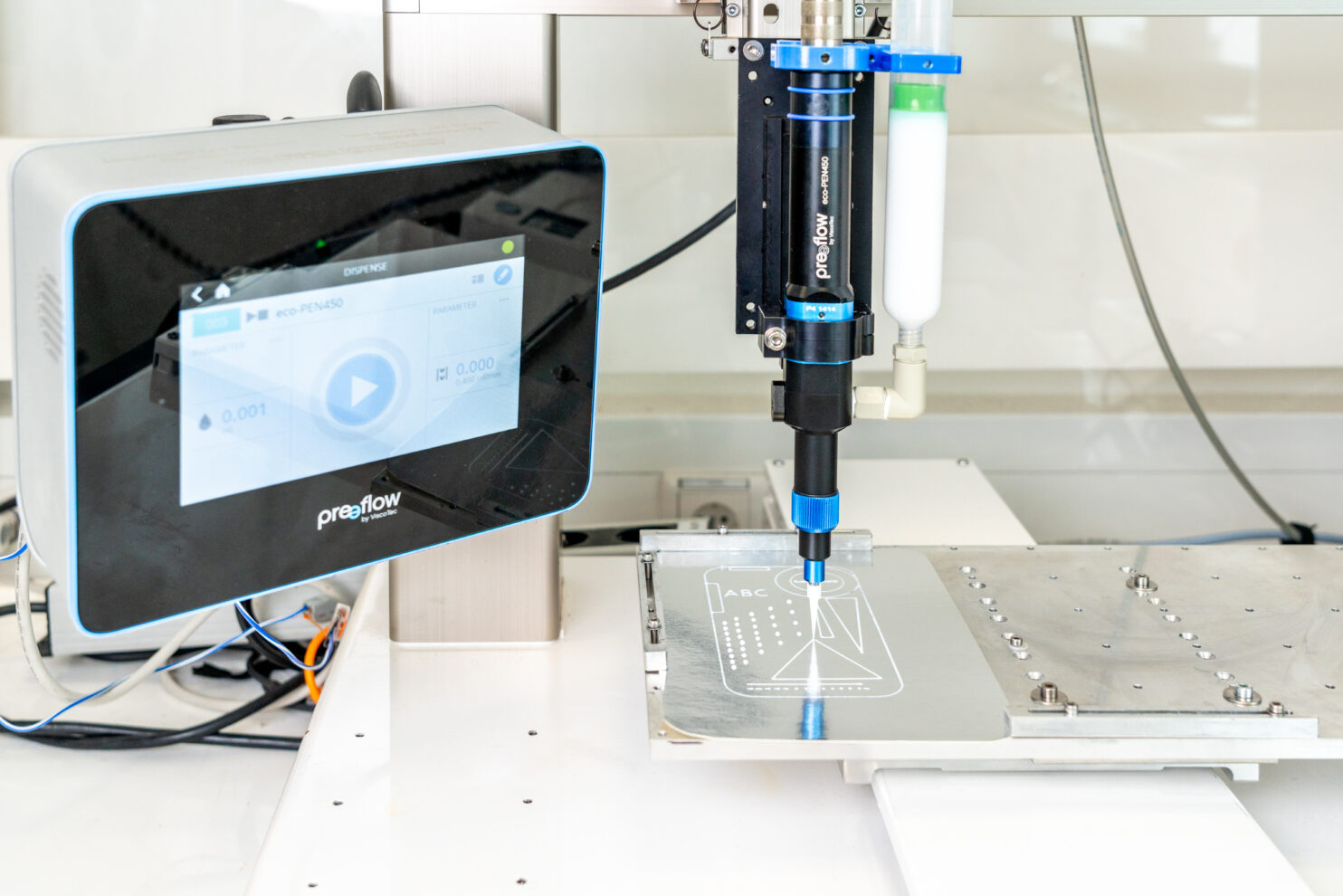

A Variety of Dispensers for Micro Dispensing Applications

Covering the entire production process with one technology Dispensing small and smallest quantities with volumetric precision and speed often presents major challenges for companies in the medical technology, automotive, electronics, biochemistry, and photonics industries. It is not uncommon for industrial manufacturing companies to integrate various dispensing systems from different suppliers into their lines in order to meet the chemical and … Read More

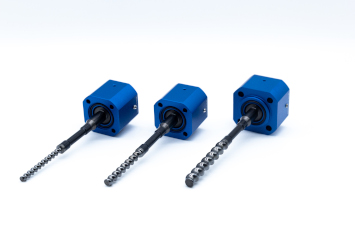

„Diamond Coated Rotor“ for preeflow

A new standard in the micro dispensing of highly abrasive Materials within the 1-component and 2-component range Precise, repeatable, and process-safe applications in the field of micro dispensing have always been the emphasis of the preeflow by ViscoTec brand. Thanks to the volumetric endless piston principle, almost all low to high viscosity materials can be processed. Solids-laden fluids, or filled … Read More

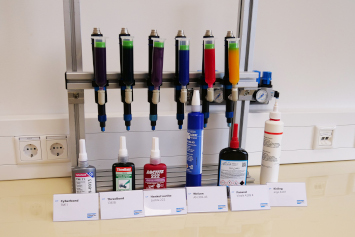

Dispensing anaerobic adhesives

Long-term tests with preeflow dispensers using one-component adhesives The word anaerobic means “without air” and therefore describes one of the two curing mechanisms in the handling of one-component adhesives: Air exclusion. Combined with the second mechanism, namely contact with metal ions, a rapid polymerization of the material is achieved. Due to their easy handling and fast curing, anaerobic adhesives enjoy … Read More

The very first eco-DUO450 has been in use for almost 10 years

A two-component dispenser shows its reliability in the dispensing of smallest quantities at SebaKMT In SebaKMT’s production facility in Baunach, an eco-DUO dispenser from the micro dispensing specialist’s preeflow line, has ensured proper dispensing from the get-go. The first eco-DUO450 two-component dispensers and was officially sold and delivered in 2011 with the serial number 0001. Precise dispensing of the high-performance … Read More

Stainless-Steel as an Alternative for preeflow Housing Components

New in the portfolio: Stainless steel kit for eco-PEN 300 to 450 Special requirements require special measures. To meet the requirements of customers and sales partners, preeflow has developed a stainless-steel kit for the eco-PEN dispensers 300, 330 and 450. These alternative housing components are now available and in stock. The stainless-steel kit is perfectly suited to convert a standard … Read More