The preeflow eco-SPRAY enables volumetric dispensing of low to high viscosity media based on the endless piston principle. A defined quantity of material is fed into the special low-flow spray chamber under processor control. The eco-SPRAY atomizes or sprays the material continuously or selectively with high edge definition and minimal overspray − for optimum spraying results. New spray needle extension … Read More

preeflow revolutionizes precision dosing

The new eco-PEN XS 180 microdispenser at productronica 2023 Right in time for this year’s edition of the productronica trade fair, preeflow has once again raised the bar with the presentation of the eco-PEN XS 180. As a leading brand for precision dosing equipment, preeflow has developed the new microdispenser especially for the lowest boundary ranges in dosing quantities, and … Read More

Dynamic mixing: Future drive monitoring and control

eco-DUOMIX: Effects of latest hardware and software updates Hard-to-mix components generally require a more complex mixing process to optimally combine the constituents. Thanks to its dynamic mixing process, the eco-DUOMIX is the perfect technical solution for processing complex media in industrial production. There has recently been a technical update. New features include a more powerful mixer motor with 100% higher … Read More

Product discontinuation eco-CONTROL EC200-DUO

eco-CONTROL EC200 2.0 DUO replaces preeflow control units eco-CONTROL EC200-DUO Technical progress ensures that our product world continues to evolve. For this reason, the control unit eco-CONTROL EC200-DUO will be discontinued from the preeflow brand product portfolio. The affected product is: eco-CONTROL EC200-DUO (part no. 20641) The subsequent eco-CONTROL EC200 2.0 DUO control unit (part no. 22604) has already been … Read More

Extending the range: Pressure tank based emptying

eco-FEED PT 5 ensures process stability when dispensing self-leveling low to medium viscosity media With the eco-FEED PT 5, ViscoTec has now added a pressure tank based emptying system to its range. This takes the Töging based company a step closer towards a complete range. In future, customers can purchase all components from supply, feed, control, and dispenser as a … Read More

Market Update: New 2-component dosing control unit complements product launch

eco-CONTROL EC200 2.0 combines the benefits of a 1-component control unit with state-of-the-art features for 2-component dosing It has been one year since the eco-CONTROL EC200 2.0 hit the market. ViscoTec, headquartered in Töging, Germany, is proud to announce the control unit now has the ability to handle 2-component dispensing. The main goal of this product development was to provide … Read More

New standard: Sustainable packaging for dispensers & co.

Regional partner is new supplier for high-quality outer cartons An incredible 40 pallets with an estimated 20,000 outer cartons have recently been stored at preeflow® – the end of a journey with which the company has actively advanced its previously-set sustainability goals for packaging materials in recent years. “Due to the COVID pandemic, we were not able to implement many … Read More

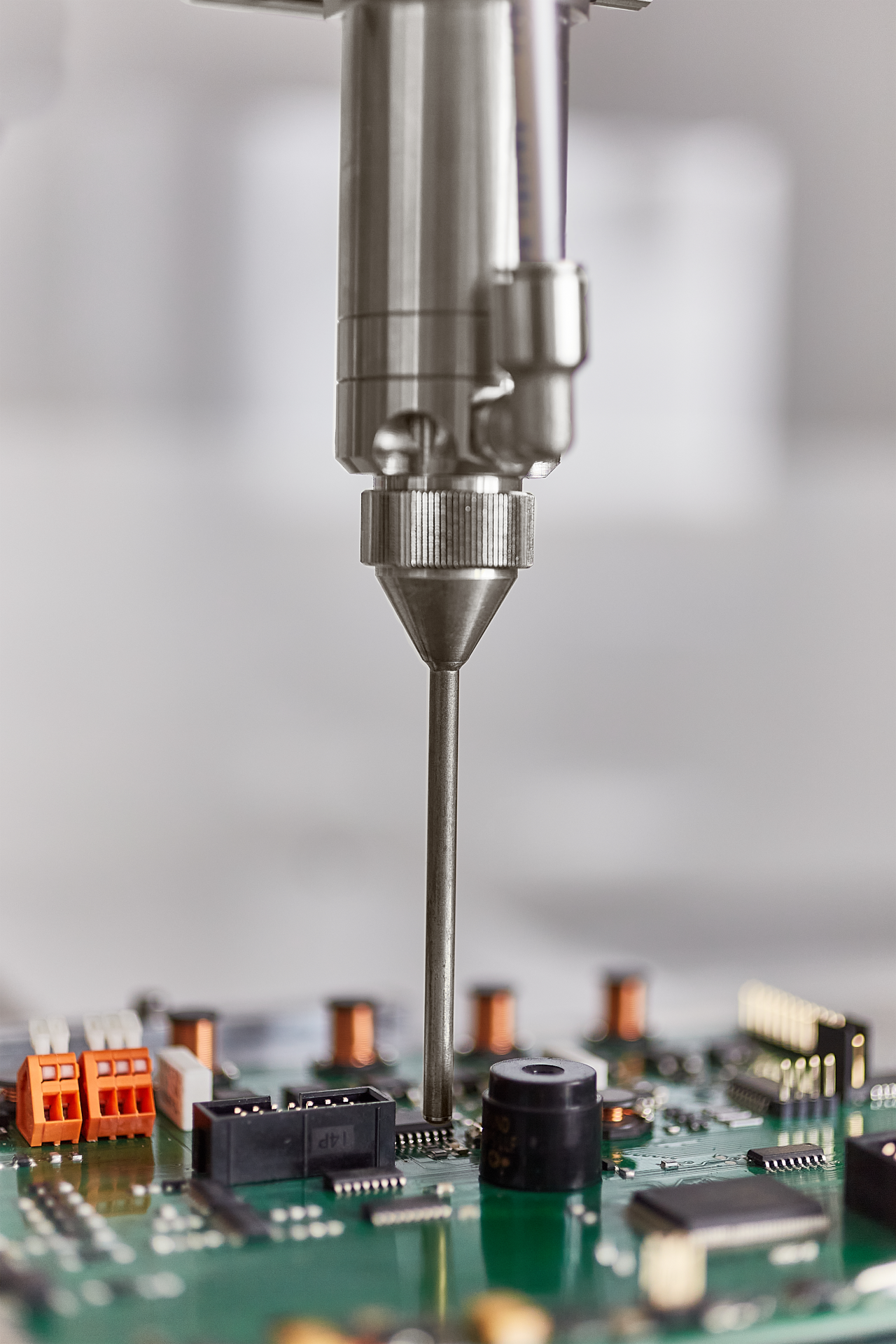

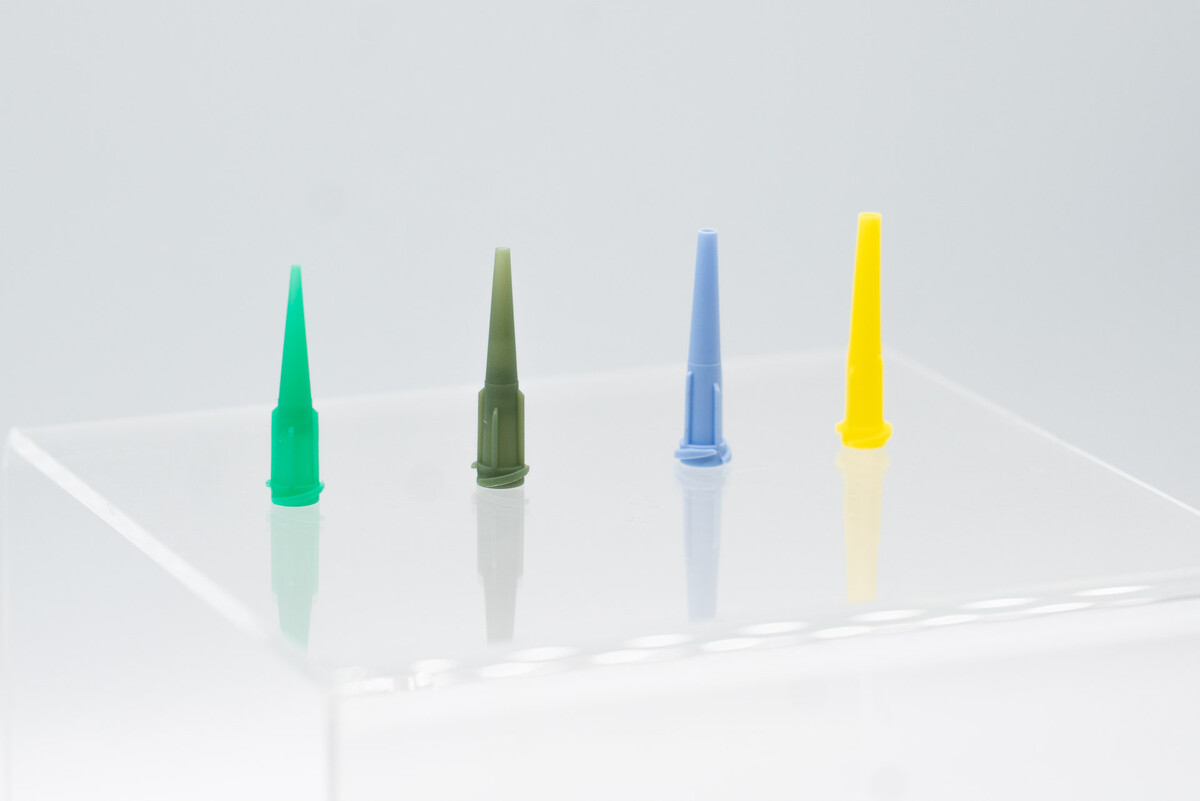

The potential for process optimization: Focus on dispensing needles

How to ensure reproducible quality in end products One of the most important parameters in a dispensing process is the resulting dispensing pressure. The optimal conditions for a functioning and process-safe setup can only be achieved by controlling this pressure. Overview of preeflow consumables dispensing needles The best example where the dispensing pressure becomes a critical parameter: The application of … Read More

Aggressive materials: double safety for the dispensing process

Uncomplicated changeover from POM plastics to stainless steel using ready-made kits Acetone, alcohol, paint or epoxy resin: These are just a selection of substances whose chemical properties challenge mechanical engineers in the implementation of customer-specific systems. However, POM plastics – technically known as polyoxymethylenes or polyacetals – are not always the best choice for components and parts. The reason is … Read More

Product discontinuation

eco-CONTROL EC200 2.0 replaces preeflow control units EC200-K and EC200-B Technical progress ensures that our product world continues to evolve. For this reason, the two control units eco-CONTROL EC200-K and eco-CONTROL EC200-B will be discontinued from the preeflow brand product portfolio. The affected products are: eco-CONTROL EC200-K (part no. 20120) eco-CONTROL EC200-B (part no. 20121) The subsequent eco-CONTROL EC200 2.0 … Read More