Fluid Dispensing Systems and Liquid Dispensers for Your Requirement

Application examples

Our fluid dispensing systems are the perfect solution for any requirement. Why? Because all our liquid dispensers and fluid dispensers can be tailored to your demands. They are suitable for a wide variety of applications and industries. Precise liquid dispensing systems, easy handling and perfect results is our expertise – your satisfaction is our top priority.

Liquid Dispensing Systems: Compatible for Every Application

When it comes to dispensing liquids the applications are as diverse as the technology. From Bonding and Glob Top to Encapsulating.

We have the right fluid dispensing system for every application.

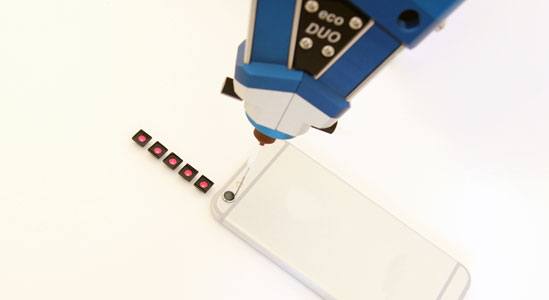

Bonding

Bonding is also referred to as structural bonding with a fluid dispenser. Adhesive dispensing is mostly used in industrial design and semi and fully automated manufacturing.

Optical Bonding

Optical Bonding improves the performance in outdoor applications and industrial displays: This process eliminates trapped air between the glass and the display.

Conformal Coating

Conformal Coating refers to the application of a protective coating. Highly viscous, thermal and UV-curing materials are used. They are applied in a thick or thin layering process.

Dam & Fill

Dam and Fill applications protect highly complex components. First, a highly viscous barrier is applied. This area is then filled by a liquid dispenser pump with a filling material.

Glob Top

Glob Top dispensing technology protects highly sensitive components and elements from vibration or external environmental influences. For this purpose, a liquid matrix is applied, which then hardens.

Underfill

Isotropic conductive adhesives require so-called Underfill applications. After the adhesive has cured, the resulting cavity is filled by a liquid dispenser pump. This dispensing technology is known as Underfill.

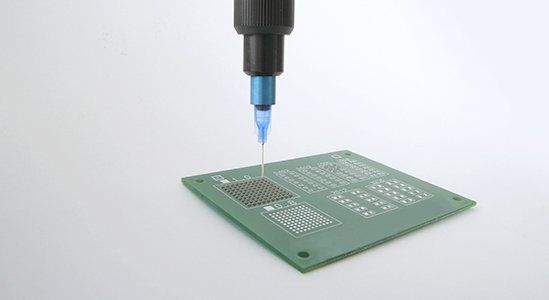

Mikrodispensing

Microdispensing refers to the dispensing of flowable material in the volume range from one microliter. This dispensing technology is used for bead dispensing, dot dispensing and 2-component dispensing.

Encapsulating

The process describes the application of an electronic potting compound. A fluid potting compound is applied to the component. The electronic component is protected during transport and against external environmental influences.

Material examples

Materials such as silicones, colours or fats differ greatly in their properties. Fluid dispensing systems must adapt to these specific requirements. That is why a wide variety of materials can be conveyed and applied using preeflow liquid dispensing equipment:

1K und 2K Epoxy

UV & light curing

heat curing

gasoline

high fill fluids

anaerobic adhesives

shear-sensitive adhesives

LED resins

toluene

thermal conductive paste

sealing agents

flavours

solder paste

RTV rubbers

silver paste

flux

industrial oils

and many more

isopropanol

cosmetics & medicines

biotechnical suspensions

silicones

epoxy resin

alcohol

thermal grease

MEK

grease

PU

paints & inks

primer

acetone

brazing paste

electrolytic solutions

perfume

Branches

Our dispensing systems for liquids are not only suitable for a wide variety of materials. They are also reliably used in a wide variety of industries:

Optics & photonics

Medical Technology

Biochemistry

LCD / LED

Photovoltaics

Laboratories

SMD / SMT

Electronic components

Semiconductors

and many more

preeflow® – automated dispensing systems

More than 25 years of experience in fluid dispensing. ViscoTec distinguishes itself with its comprehensive know-how in dispensing technology. In 2008, this wealth of experience was expanded with the introduction of the preeflow brand. With success: For more than 15 years, preeflow has stood for precise and purely volumetric dispensing of fluids in small and very small quantities. All over the world, a wide variety of industries rely on preeflow dispensing products. Always following our philosophy: Smaller, more precise, economical.